In the DCS milling machine family, the DCX™ is the “sassy one” because, despite its compact dimensions and its amazingly affordable purchase price, it brings 100% industrial thinking to your laboratory.

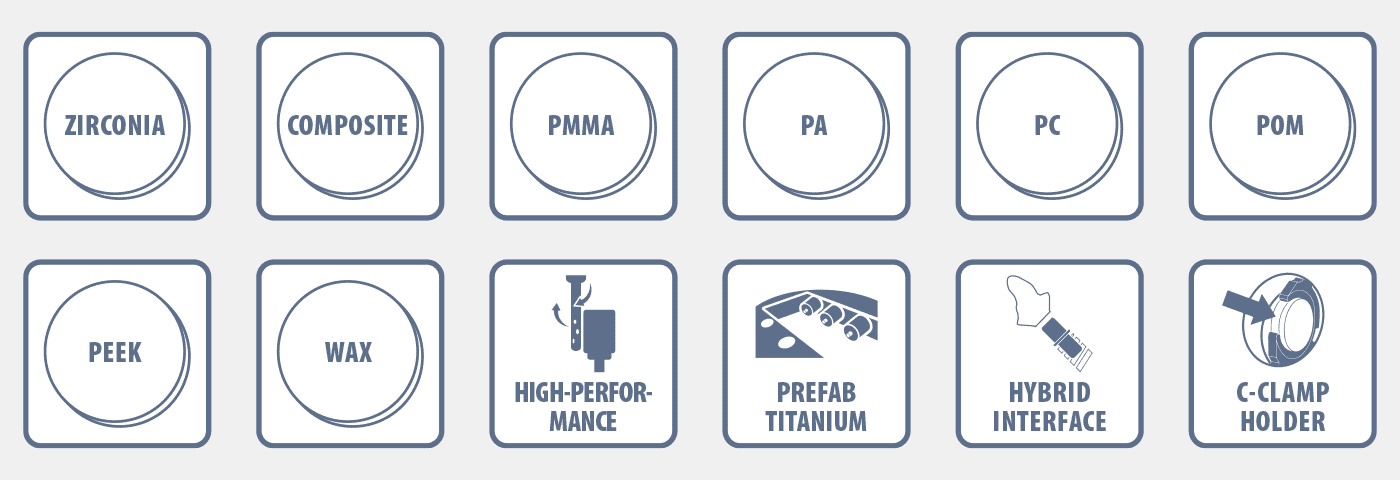

The DCX™ is focussed on the precise, fast and reliable production of aesthetic pieces and corresponding interfaces from primarily softer materials.

Thanks to its low resonance, the special frame design significantly increases precision and ensures special dynamics in the milling process. Brilliant restoration surface structures meet the highest aesthetic demands.

Bearing-guided axles on both sides provide high-precision milling in all blank regions. Holes through the blank are precisely milled and not misaligned on one side due to the pressure of the spindle. Double support also means a reduction of resonances when processing all materials, giving higher precision, delicate results and a more natural look.

Using a measurement blank and a tactile probe, the system automatically collects the required data and checks in the machine control system that the axes are sufficiently precise. The user has a constant overview and can even change the milling spindle manually if necessary.

Thanks to automatic calibration, titanium abutments can be produced in a highly targeted manner by editing the pre-milling processes.

The system determines the exact position tactilely and guarantees safe and precise production of prefaces regardless of the possible tolerance deviations in the holder.

The tool moves the spindle, not the other way round. This has the following advantages for you:

• Very quick changeover time of 5 sec.

• The spindle maintains its position and precision

• The tool is protected against dirt

A sophisticated impulse jet system removes dust and chips from the object

so that both precision on the object and cleanliness throughout the cutting chamber are increased.

In the DCX system, tools, blanks and holders can be read by the mobile handheld scanner and the data automatically transferred to the control interface. Of course, material freedom is maintained for manual use. Clear advantages for system customers are the optimum convenience and effective protection against application errors.

The open blank holder provides maximum freedom in the area accessible to the milling machine, with full flexibility of all DCS holder systems for prefabs and measuring blanks. Splints and drilling templates can be processed at previously unreachable angles and the front tooth aesthetics of even large restorations suddenly shine with very natural surfaces.

The DCX also benefits from the special module concept. As a result, service operations at home and abroad can be handled unusually quickly and in a resource-efficient manner. DCS service teams can operate effectively and with high precision worldwide. Of course, the cheeky DCX system also impresses with its low-maintenance continuous operation.

Dental Concept Systems GmbH

Gieselwerder Str. 2

D – 34399 Wesertal

Phone : + 49 (0) 5572 – 3021010

Fax: + 49 (0) 5572 – 3021099

Email : info.dcs@bredent-group.com