For all those

who aim to go higher!

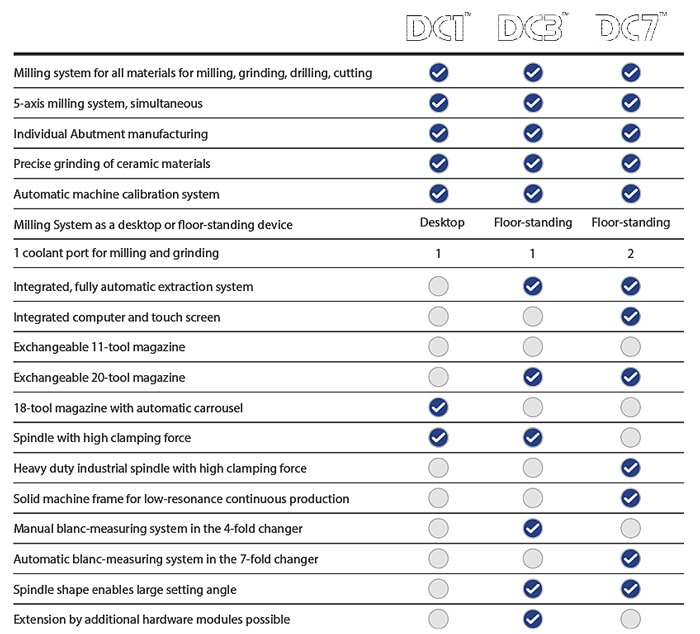

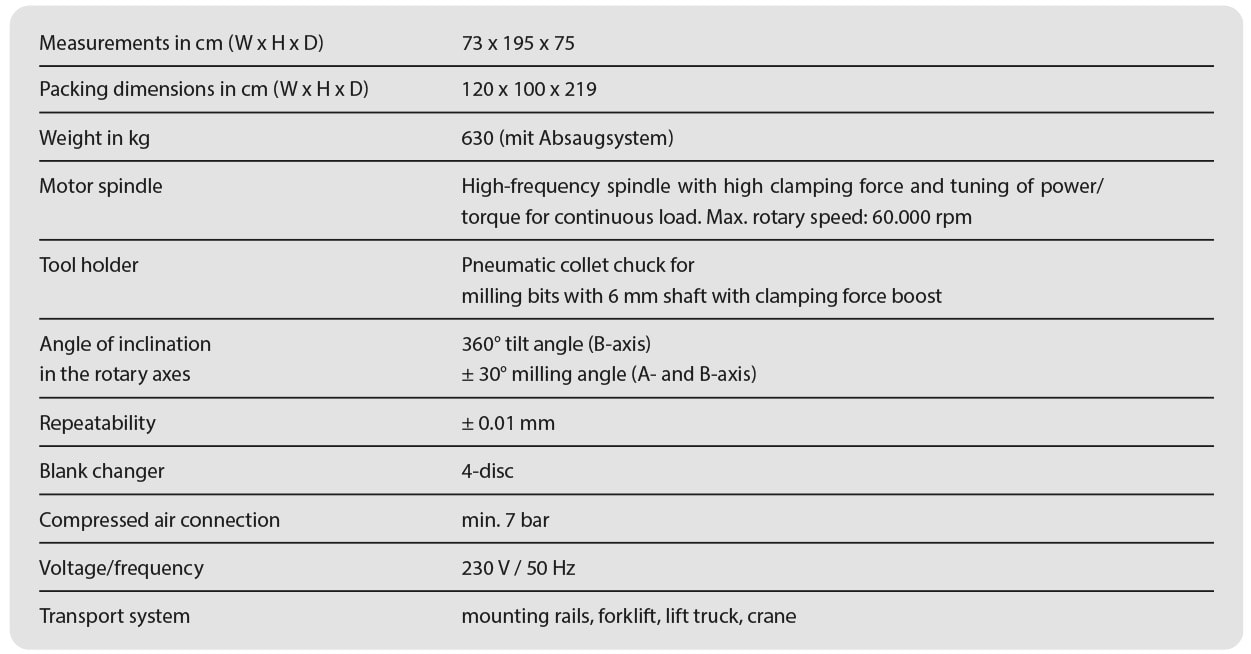

The DC7™ is a highly capable system for the larger laboratory desiring consistency in demanding production situations. The system also offers the user great comfort in terms of user-friendly management.

The modern control management is specifically designed for the system and the use of high-performance industrial CAM software. Information is presented clearly on a modern integrated touch screen. The DC7™ Allows modern laboratories entry into the superclass of dental milling with a manageable investment to secure their position with a competitive edge for many years.