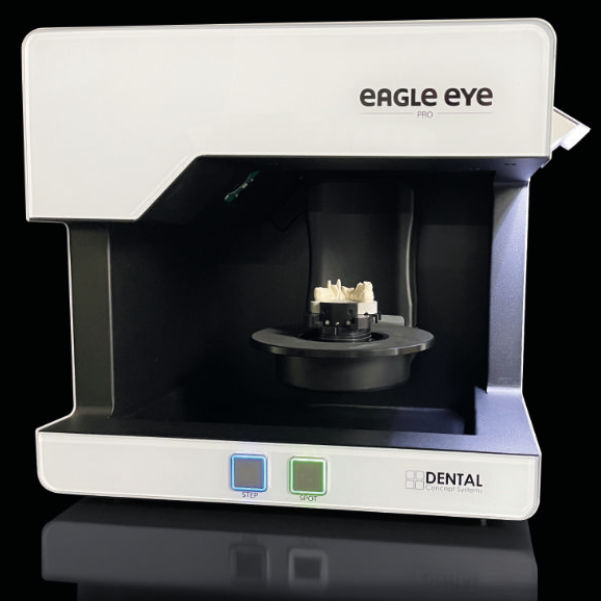

Eagle Eye: The modern scanning system for the perfect combinationsl

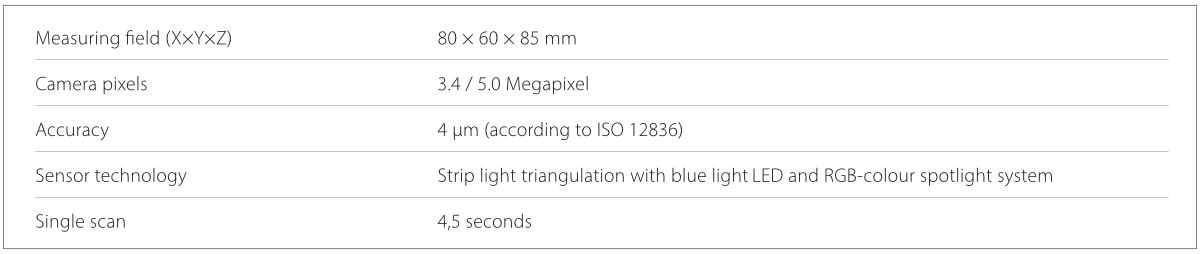

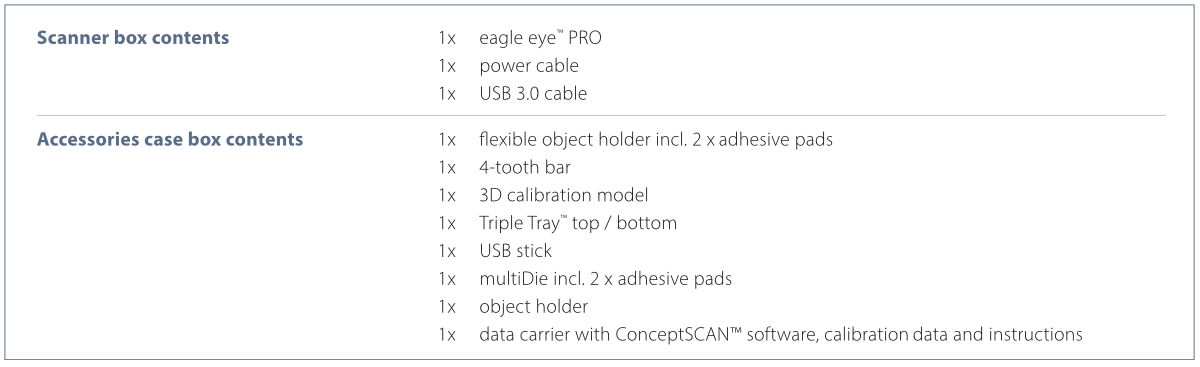

The eagle eye™ scanner impresses with its precision, speed, longevity and huge range of functions for the complete spectrum of dental technology. The symbiosis between the high-quality hardware and the clear and user-friendly user software conceptSCAN™

enables a perfect digital preparation for further processing in the expertCAD™ (powered by exocad™) CAD software.