ADVANTAGE!

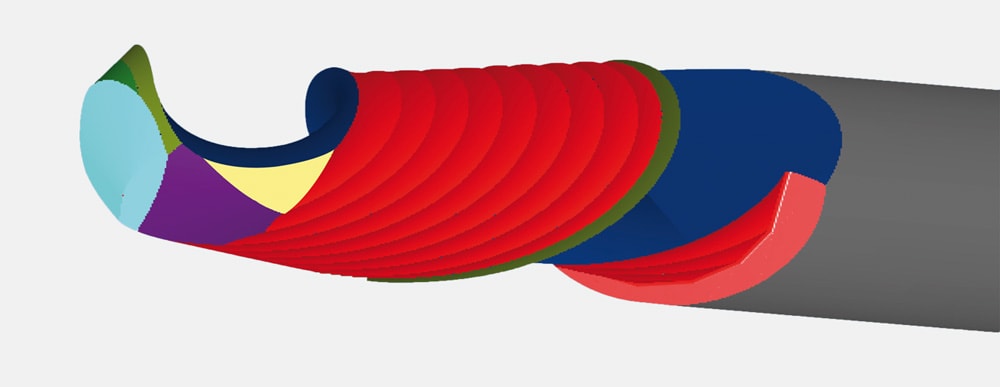

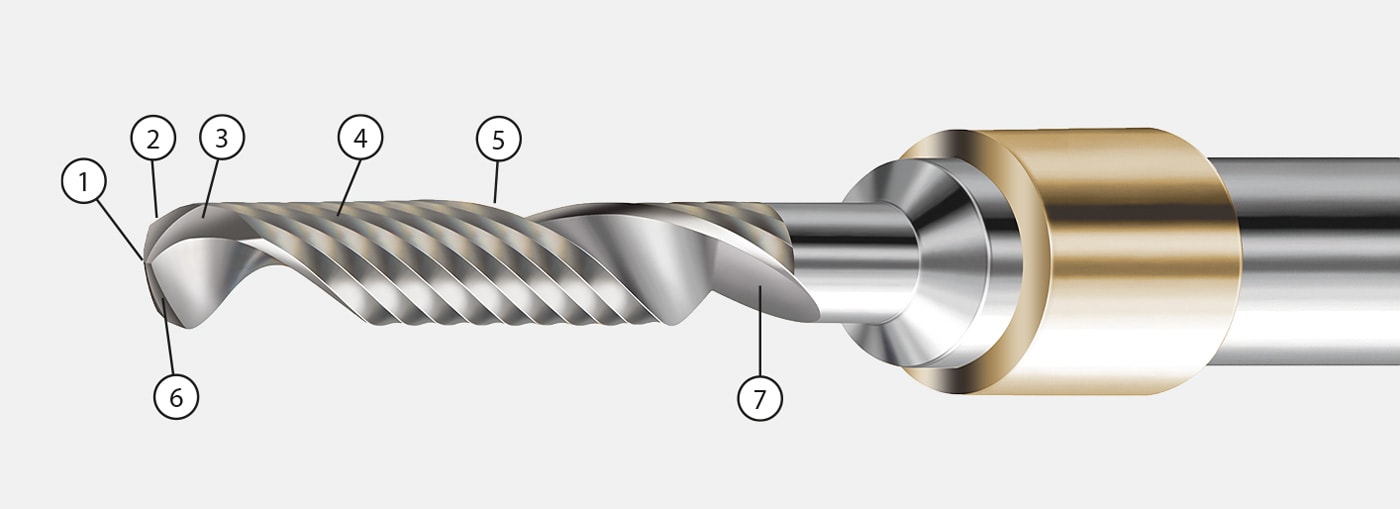

Thanks to a special cutting geometry, it is also possible to take thermoplastic materials, which have properties which allow them to spread quickly and clog up the tool, and mill them without water cooling.

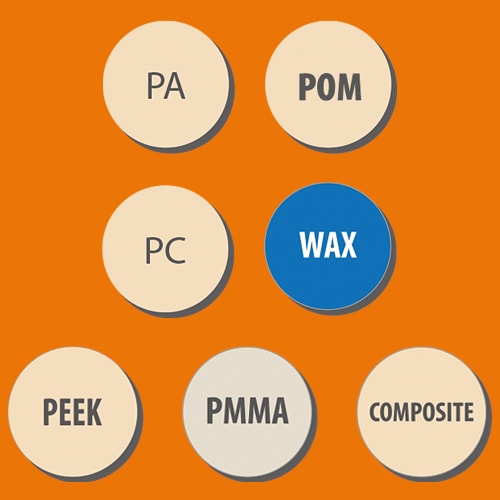

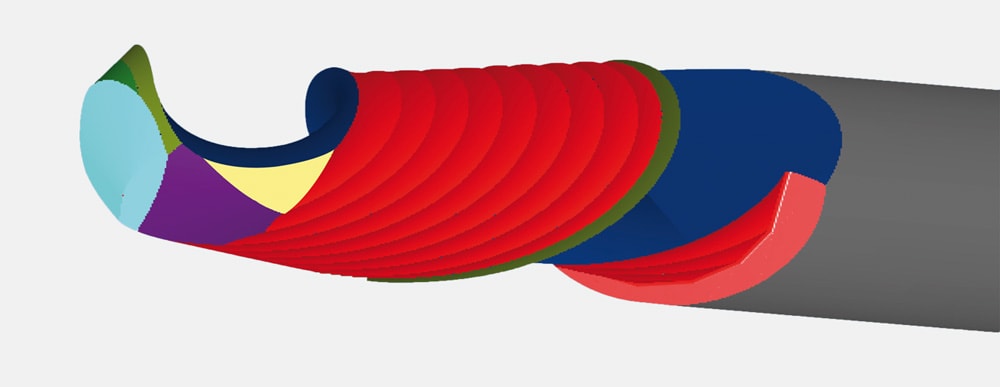

The innovative cutting geometry of the ORANGE LINE – bre.CAM cutters enables the dry processing of PMMA, PEEK

and other thermoplastic materials in CNC milling machines.

Due to the low heat generation of the ORANGE LINE – bre.CAM cutter during the milling process, easily fusing materials can be machined without the need for water cooling. Warping of delicate structures is avoided. Even at a high

feed rate, the ORANGE LINE – bre.CAM cutter generates a smooth surface on the workpiece thanks to its patented cutting of multiple rear reliefs. This saves time during the milling process and further processing.

Thanks to a special cutting geometry, it is also possible to take thermoplastic materials, which have properties which allow them to spread quickly and clog up the tool, and mill them without water cooling.

Dental Concept Systems GmbH

Gieselwerder Str. 2

D – 34399 Wesertal

Phone : + 49 (0) 5572 – 3021010

Fax: + 49 (0) 5572 – 3021099

Email : info.dcs@bredent-group.com