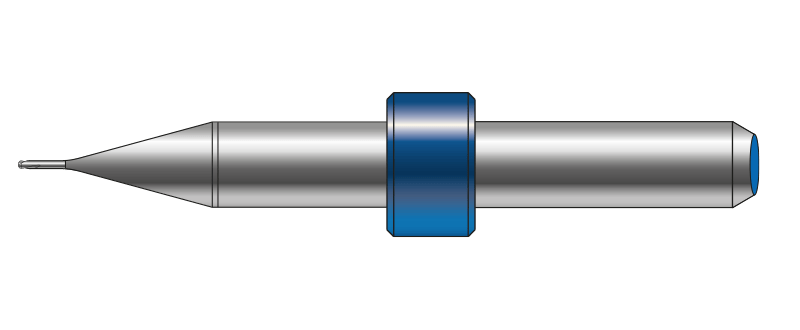

The cutting edge geometry of these tools is designed to cope with high stress during hard machine cutting. The BLUE LINE coating improves resistance to abrasion and features an impressive resistance to oxidation and hot hardness.

The very low friction value of the tools reduces heat development and milling forces at the cutting edges. Flat milling bits for the machining of abutments and bridges as well as, high-feeding-rate milling bits for speed-roughing are available. The machining of CoCr presents a particular challenge for the milling tools.

Dental Concept Systems tools are designed

for the dry machining of restorations and are suitable in quality and shape for the production of primary and secondary parts as well as for large bar constructions. Geometries and coatings are no coincidence but the result of many years of experience with the DCS milling systems and the software components developed in-house.

Grave errors can be made when purchasing CoCr blanks.

Non-machinable constituents or inhomogeneous inclusions can quickly ruin a complete set of milling burs and vastly overheat

the milling areas. The consequential damages outweigh

any offer of savings.

Dental Concept Systems GmbH

Gieselwerder Str. 2

D – 34399 Wesertal

Phone : + 49 (0) 5572 – 3021010

Fax: + 49 (0) 5572 – 3021099

Email : info.dcs@bredent-group.com